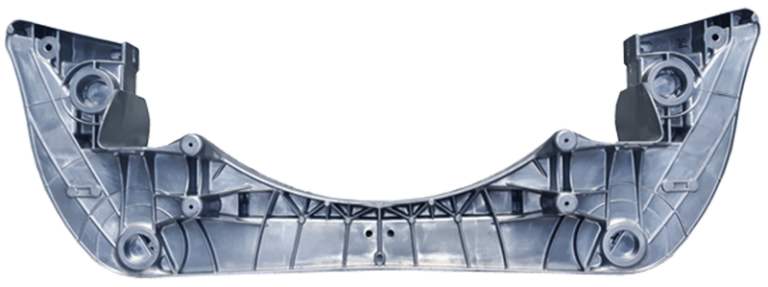

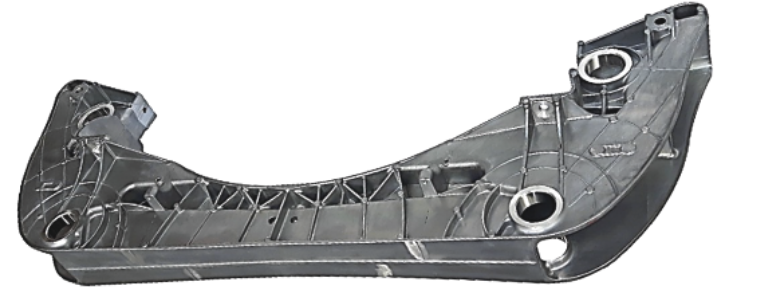

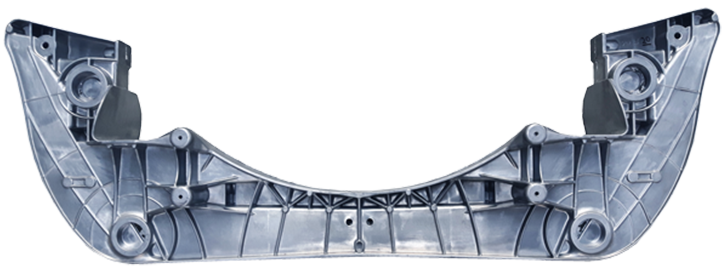

New HPDC

More load capacity, lower consumption

More load capacity, lower consumption

Die-cast aluminium allows a 47% weight reduction compared to sheet steel production.

Lightweight aluminium components for the automotive sector allow a reduced fuel consumption and, at the same time, a greater load capacity.

The use of die-cast aluminium permits a lower CO2 emissions into the atmosphere and a substantial improvement in the Life Cycle Assessment of each product, thanks to its ability to be 100 per cent recycled.

A huge step forward towards sustainability not only for the automotive world, but for multiple sectors.

Awarded for Innovation by AIM (Italian Metallurgy Association) during international conference HighTechDieCasting 2016

Final Nominee for European Aluminium Award 2016 – Dūsseldorf

Awarded for innovation by METEF during international trade fair METEF 2017

Rob.y is a complete electrically driven marching chassis with integrated autonomus driving features, capable of enabling multiple uses and services and intended for light vehicles that will operate in urban, private and industrial settings.

Would you like to receive more information?

Fill out the form: Alunext staff will get back to you as soon as possible.